ECN simply stands for Eastman Color Negative. It was a processing system that evolved into ECN-2 when research enabled faster and more environmentally friendly development processes (and thus faster photo lab turnaround time!). As a result, ECN-2 became the industry standard for all current motion picture color negative development till today. In short, it provides a cinematic look that you see in most movies today (due to the REMJET layer being removed).

The reason why the ECN-2 process exists is because the remjet layer on the back of the film provides protection from scratches, static and halation around highlights. This black coating on the film must be removed before development. It is not intended to be processed in the C-41 color negative development process. Even though the process may be similar to C-41 development, there is an additional step that differentiates the two. ECN-2 process includes what is called a prebath – this removes the adhesive holding a layer of black carbon off the backing of the film, or remjet layer (so do not bring it to your local lab and try to develop as C-41, your local lab will not love you for that, bring it to places that specifically develop ECN-2 film, 35M Pro for example).

The remjet layer is on the back of this film for multiple reasons:

1) It acts as a layer that significantly dampens halation (light passing through the film and bouncing back into the emulsion).

2) The remjet layer displaces static build-up. In the motion picture industry, film pulls through a camera at 24 frames per second (or more). This rapid movement through the camera can build up static. When static discharges on film, it creates a spark that shows up on your film.

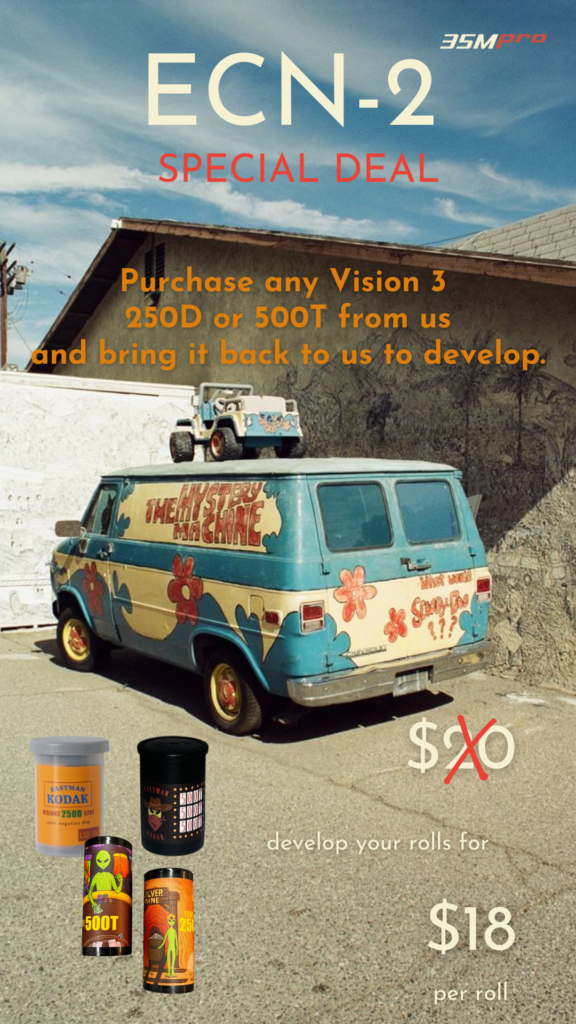

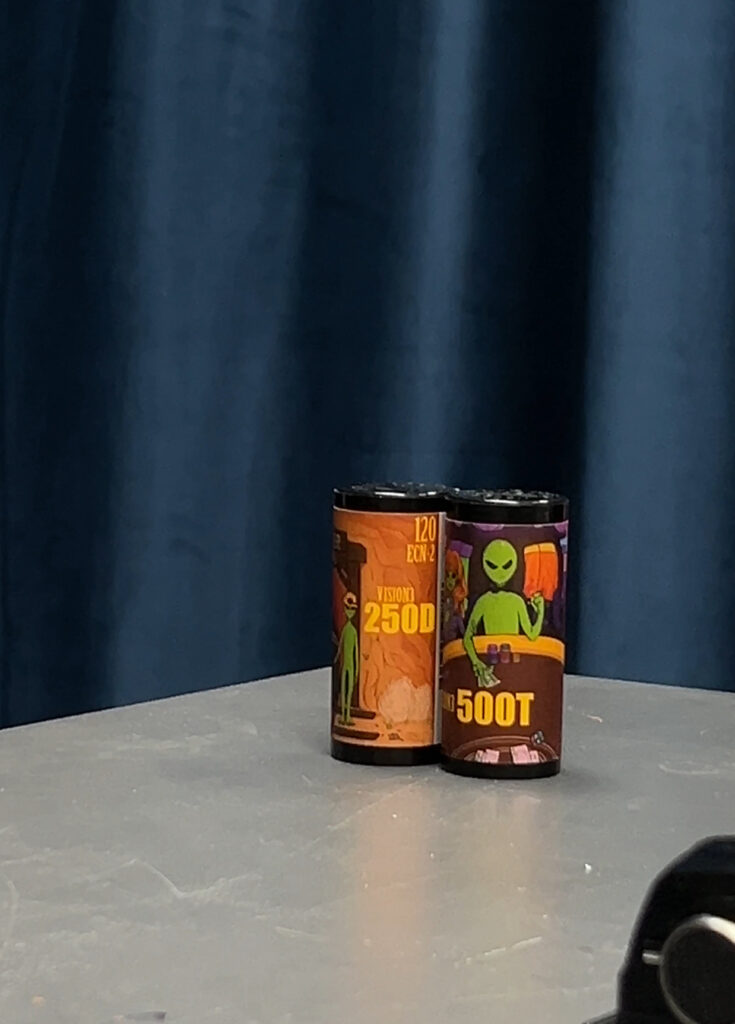

Since we now offer ECN-2 development, we also offer Kodak Vision 3 film stocks in both 35mm and 120 spooled by aliens at @analogabduction.

We have Vision 3 250D and 500T in stock and we love them both!

If you’re interested in getting a roll of Kodak Vision 3 or you want to drop off a roll of ECN with us, stop by the shop today!